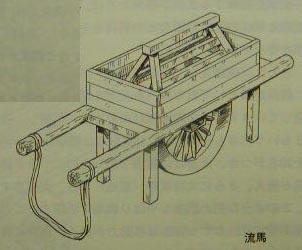

The design basis for the modern wheelbarrow was based on a design brought up in China in the 1st and 2nd century.  They were made out of wood and were primarily used to transport food, supplies and transport wounded soldiers off the battlefield. There are drawings and tombs to show what we would call a wheelbarrow. The drawing suggest that they would have a large front wheel with some wooden box/storage area to carry the load.

They were made out of wood and were primarily used to transport food, supplies and transport wounded soldiers off the battlefield. There are drawings and tombs to show what we would call a wheelbarrow. The drawing suggest that they would have a large front wheel with some wooden box/storage area to carry the load.

There was another design implemented by the Chinese around the 3rd century. This had a centrally mounted wheel with one person on either end to help stabilise it and an ox pulling it along.  This design allowed for a larger storage area as it could now transport up to 6 people. This design was much better than the European counterpart created later on as the load was fully taken off the driver off the cart. This was because the central wheel took all of the weight and left the driver to just steer. Whereas the European design would be able to take about half of the weight of the load, leaving the driver to carry the other half. This made the Chinese version much more manoeuvrable despite the large size. More in-depth detail can be found here.

This design allowed for a larger storage area as it could now transport up to 6 people. This design was much better than the European counterpart created later on as the load was fully taken off the driver off the cart. This was because the central wheel took all of the weight and left the driver to just steer. Whereas the European design would be able to take about half of the weight of the load, leaving the driver to carry the other half. This made the Chinese version much more manoeuvrable despite the large size. More in-depth detail can be found here.

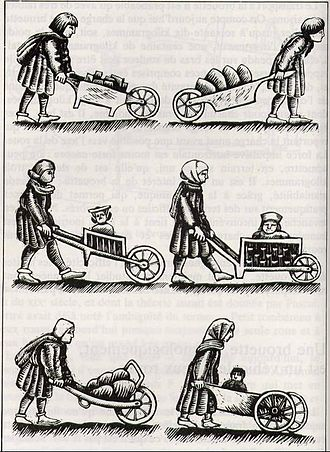

This idea then slowly spread across into mainland Europe in the late 12th and early 13th century, where it was mainly used for agriculture and transporting crop and livestock to the market.  The uses began to spread to construction, mining and for wartime use. Each country within Europe tended to use their own design, with French, Flemish, and Dutch wheelbarrows usually had a rack to rest the load or basket against. Swiss wheelbarrows had solid wheels, while English ones had four feet and spoked wheels.

The uses began to spread to construction, mining and for wartime use. Each country within Europe tended to use their own design, with French, Flemish, and Dutch wheelbarrows usually had a rack to rest the load or basket against. Swiss wheelbarrows had solid wheels, while English ones had four feet and spoked wheels.

From then until the early 19th century the design hardly changed. Then the design changed to have a more rounded and sloped edges, compared to the flat and box like design of before.  This made it much easier to load and unload the wheelbarrow. Towards the end of the century, wheelbarrows made out of metal where created. This design was heavy, but durable. It featured a design very similar to modern day wheelbarrows, with two handles and support legs and a singular wheel out in front to maximise efficiency. However, the then metal wheel would make it hard to manoeuvre and would often dig into the soil.

This made it much easier to load and unload the wheelbarrow. Towards the end of the century, wheelbarrows made out of metal where created. This design was heavy, but durable. It featured a design very similar to modern day wheelbarrows, with two handles and support legs and a singular wheel out in front to maximise efficiency. However, the then metal wheel would make it hard to manoeuvre and would often dig into the soil.

Over the next 45 years, wheelbarrows would play a crucial role in both WW1 and WW2, less so in WW2 but it was especially important in WW1 when there was less strain on moving supplies quickly and everything being mechanised.  The wheelbarrow was usually used to transport shells, ammunition, wounded soldiers and to help excavate the dirt to build the trenches. The wheelbarrows used in WW1 were primarily made out of wood, as this was lightweight meaning it is less likely to sink into the mud. However, in WW2 there were considerably less wheelbarrows used as they were replaced by horses, carts and mechanised vehicles in order to move supplies quickly. Though they did see some action when helping wounded soldiers off the battlefield and did have some other uses for carrying supplies in within a small area. These wheelbarrows tended to be made out of wood due to metal being needed for much more important machinery.

The wheelbarrow was usually used to transport shells, ammunition, wounded soldiers and to help excavate the dirt to build the trenches. The wheelbarrows used in WW1 were primarily made out of wood, as this was lightweight meaning it is less likely to sink into the mud. However, in WW2 there were considerably less wheelbarrows used as they were replaced by horses, carts and mechanised vehicles in order to move supplies quickly. Though they did see some action when helping wounded soldiers off the battlefield and did have some other uses for carrying supplies in within a small area. These wheelbarrows tended to be made out of wood due to metal being needed for much more important machinery.

After the WW2 and into the 1950s, wheelbarrows began to be made out of cast steel or iron with basic rubber wheels, that had no inner rim. Then into the 1960s and 70s different designs began to immerge. Ideas such as bigger buckets, different tyres and wheel and a change in the material, as polythene began being used as the bucket. The tyre and wheels changes to make the tyre wider and bigger so it had a bigger surface area, meaning it is less likely to sink into the mud. The wheels had inner rims which provided a much more stable point of attachment for the structure and it also gave much more support to the tyre when going over bumps.

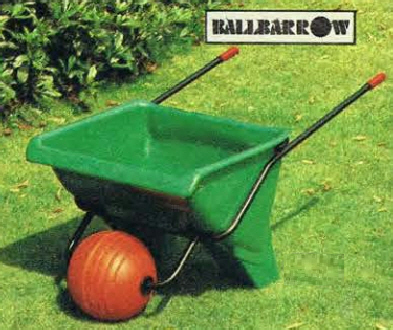

A cool invention that was sprouted from the 1970s was the Ballbarrow invented by James Dyson.  This wheelbarrow a roughly spherical wheel. This meant that it was much harder for it to get bogged down in the dirt. It was also a lot more stable when carrying heavier loads due to how little lateral movement there would be. This was because of the spherical shape balancing the spread of the weight more evenly than a normal tyre. The design was so good it is still going strong 50 years later.

This wheelbarrow a roughly spherical wheel. This meant that it was much harder for it to get bogged down in the dirt. It was also a lot more stable when carrying heavier loads due to how little lateral movement there would be. This was because of the spherical shape balancing the spread of the weight more evenly than a normal tyre. The design was so good it is still going strong 50 years later.

Moving on to modern day, there are now many different types of wheelbarrows available on the market. Galvanised and a wide variety of wheels and materials to choose from. A galvanised wheelbarrow is when the metal bucket is protected from rust through galvanisation (when a more reactive metal reacts with oxygen in the air and water instead of the metal used for the bucket). This helps to prevent rust and corrosion to the wheelbarrow, meaning it can be stored and used outside in all weather and not make a difference to the looks. Wheelbarrows can now come with more wheels, with some brands offering a 4 wheeled version, others do 2- and 3-wheels versions. There are also a couple versions of tyres available, pneumatic, solid and puncture proof. A pneumatic wheel is a more traditional wheel that has air inside of the tire. Whereas a solid tyre is solid rubber in the shape a tyre. It has no air inside, therefore making it puncture proof and extremely heavy duty. The puncture proof tyres are similar to the solid tyres but they have a much thinner but stronger layer of rubber and a much larger inner rim. There are also adaptations of the Ballbarrow see today by Walsall with their Duraball Wheelbarrow. The main material used to this day is stainless steel but can be galvanised with zinc or painted in many colours. Wheelbarrow are also now being made out of strong plastics.